面积光学自由曲面面形精度非接触测量技术

发表时间:2018-03-27 11:19:31

一、成果简介

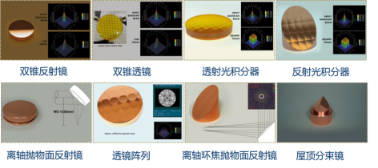

现代光学技术的迅猛发展,对光学零件的精度尤其是表面精度与形貌提出了越来越高的要求。传统接触式的测量方法精度高,但是由于接触力的存在容易损坏工件表面,非接触测量无接触力,对被测工件表面无任何划伤,测量效率高。本项目基于自动跟踪原理研发了的非接触式轮廓仪,能够实现光学自由曲面面形特征的高效精密测量。

主要创新:

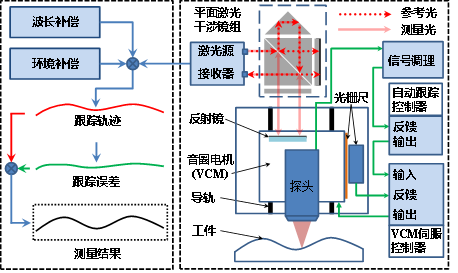

1、提出了探头自动跟踪的测量原理。自主开发音圈电机平台和控制器,实现了探头快速、精确地跟踪样品形貌,弥补了探头量程小的不足;

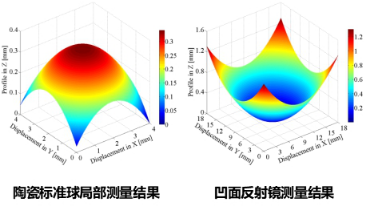

2、提出了跟踪轨迹和跟踪误差同步测量的方法。结合激光干涉仪和色散共焦位移传感器的优点实现了高精度面形测量;

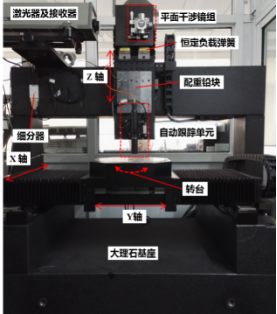

3、建立了四轴运动平台扫描系统,能够实现栅格式和螺旋式扫描测量;

4、自聚焦系统等主要部件实现了自主化、产品化。

二、重要论文及获奖:

1. Zhu W, Zhu Z, Shi Y, et al. A novel piezoelectrically actuated 2-DoF compliant micro/nano-positioning stage with multi-level amplification.[J]. The Review of scientific instruments. 2016, 87(10): 105006.

2. Zhu W, Xing Y, Ehmann K F, et al. Ultrasonic elliptical vibration texturing of the rake face of carbide cutting tools for adhesion reduction[J]. INTERNATIONAL JOURNAL OF ADVANCED MANUFACTURING TECHNOLOGY. 2016, 85(9-12): 2669-2679.

3. Bai X, Niwas S I, Lin W, et al. Learning ECOC Code Matrix for Multiclass Classification with Application to Glaucoma Diagnosis[J]. JOURNAL OF MEDICAL SYSTEMS. 2016, 40(784).

4. Chen Y, Cai Y, Shimizu Y, et al. On-machine measurement of microtool wear and cutting edge chipping by using a diamond edge artifact[J]. PRECISION ENGINEERING-JOURNAL OF THE INTERNATIONAL SOCIETIES FOR PRECISION ENGINEERING AND NANOTECHNOLOGY. 2016, 43: 462-467.

5. Chen Y, Cai Y, Shimizu Y, et al. Ductile cutting of silicon microstructures with surface inclination measurement and compensation by using a force sensor integrated single point diamond tool[J]. JOURNAL OF MICROMECHANICS AND MICROENGINEERING. 2016, 26(0250022).

6. Zhu W, Yang S, Ju B, et al. Scanning tunneling microscopy-based on-machine measurement for diamond fly cutting of micro-structured surfaces[J]. PRECISION ENGINEERING-JOURNAL OF THE INTERNATIONAL SOCIETIES FOR PRECISION ENGINEERING AND NANOTECHNOLOGY. 2016, 43: 308-314.

7. Sun A, Bai X, Ju B. A new method for evaluating the degeneration of articular cartilage using pulse-echo ultrasound[J]. REVIEW OF SCIENTIFIC INSTRUMENTS. 2015, 86(0343013).

8. Chen Y, Wang S, Shimizu Y, et al. An in-process measurement method for repair of defective microstructures by using a fast tool servo with a force sensor[J]. PRECISION ENGINEERING-JOURNAL OF THE INTERNATIONAL SOCIETIES FOR PRECISION ENGINEERING AND NANOTECHNOLOGY. 2015, 39: 134-142.

9. Zhu W, Yang S, Ju B, et al. On-machine measurement of a slow slide servo diamond-machined 3D microstructure with a curved substrate[J]. MEASUREMENT SCIENCE AND TECHNOLOGY. 2015, 26(0750037).